Cold Forming Die

-

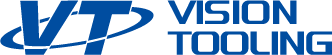

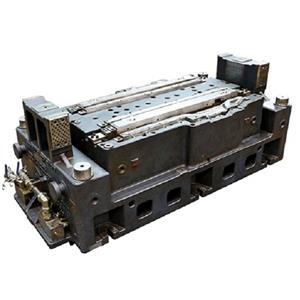

Progressive Die

Cold-Forming Tool, a division of Vision Tooling Group, currently employs over 200 engineers and more than 220 toolmakers. Equipped with 129 sets of CNCs and 17 sets of presses up to 2000T, we provide customers an integrated solution with high-quality tools and services.

Email Details

This division focuses on designing and manufacturing cold-forming tools to produce automotive metal parts including big progressive die, transfer die, and tandem die... Above 32% of our cold-forming tool business is progressive die.

Progressive Die is the ideal manufacturing method during the metal forming and it's often applied in high-volume production for its quick run speed and short set time. Besides, less metal scrap waste is another big advantage.

Metals usually used in progressive die:

1. Brass

2. Steel

3. Stainless Steel

4. Aluminum

5. Copper -

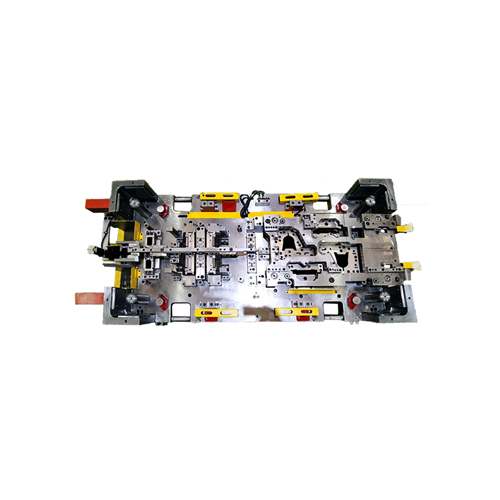

Transfer Die

Cold-Forming Tool, a division of Vision Tooling Group, currently employs over 200 engineers and more than 220 toolmakers. Equipped with 129 sets of CNCs and 17 sets of presses up to 2000T, we provide customers an integrated solution with high-quality tools and services.

Email Details -

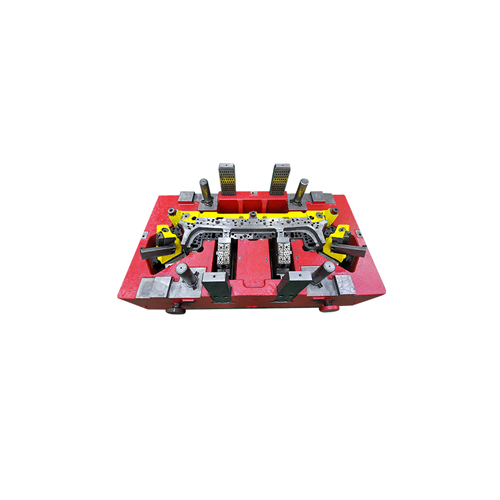

Tandem Die

Cold-Forming Tool, a division of Vision Tooling Group, currently employs over 200 engineers and more than 220 toolmakers. Equipped with 129 sets of CNCs and 17 sets of presses up to 2000T, we provide customers an integrated solution with high-quality tools and services.

Email Details

This division focuses on designing and manufacturing cold-forming tools to produce automotive metal parts including big progressive die, transfer die, and tandem die... Above 31% of our cold-forming tool business is tandem die.

Tandem Dies is a die manufacturing method in which the customized part is processed in a plurality of dies in different operations. This method is generally preferred for parts that have fewer production orders or that can not be produced by other tooling methods.