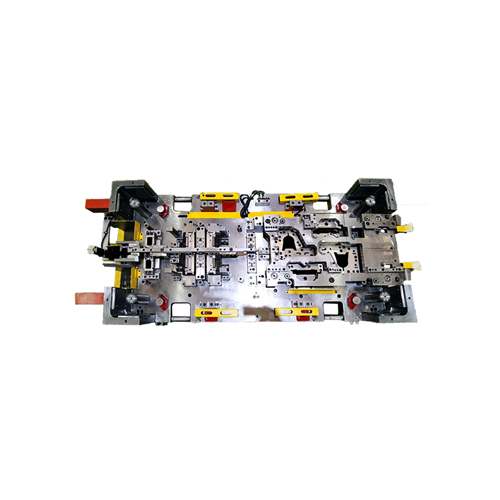

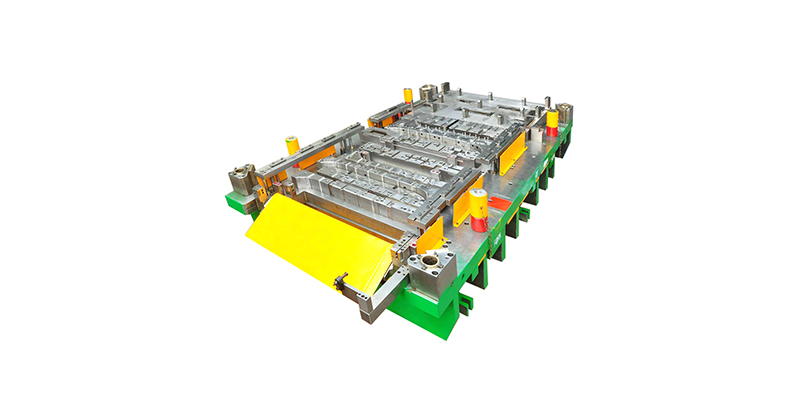

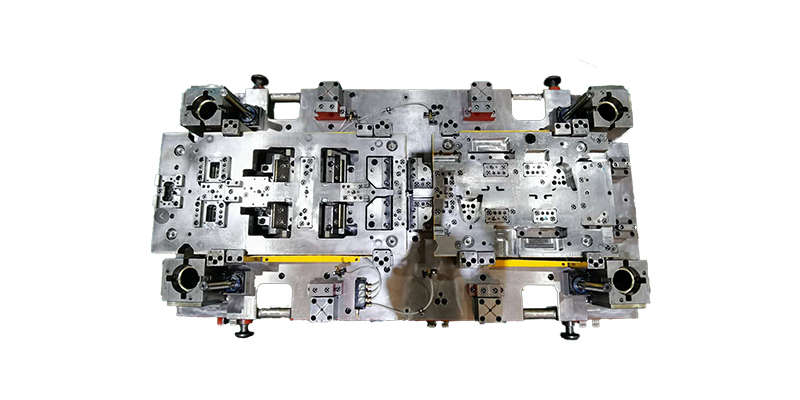

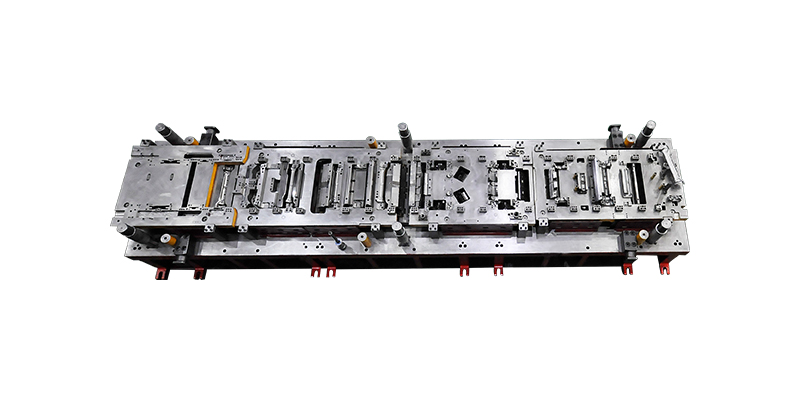

Progressive Die

- Vision Tooling

- China

- 28-34 wks

- Full

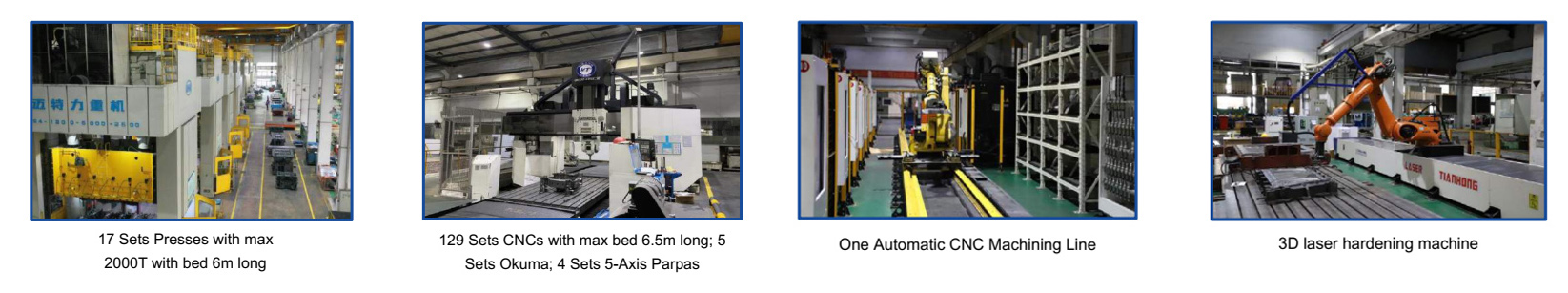

Cold-Forming Tool, a division of Vision Tooling Group, currently employs over 200 engineers and more than 220 toolmakers. Equipped with 129 sets of CNCs and 17 sets of presses up to 2000T, we provide customers an integrated solution with high-quality tools and services.

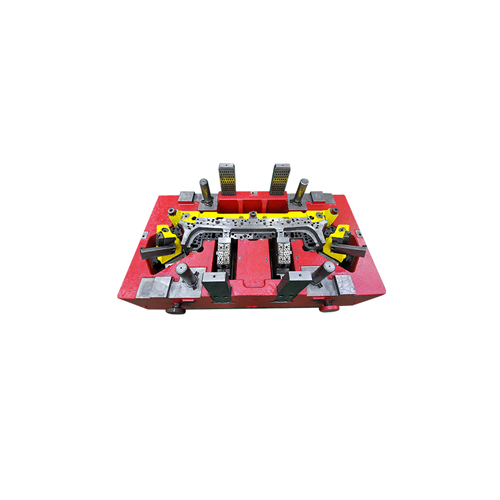

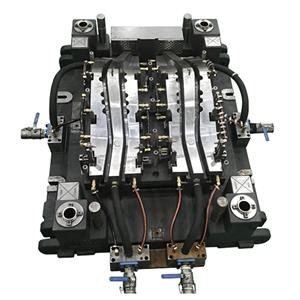

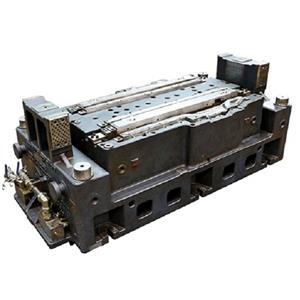

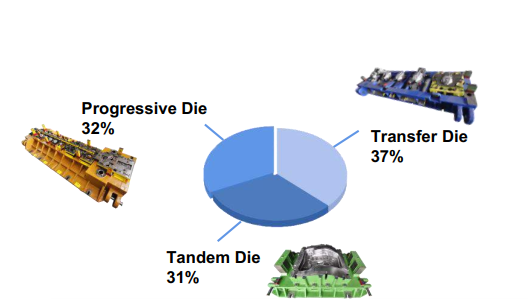

This division focuses on designing and manufacturing cold-forming tools to produce automotive metal parts including big progressive die, transfer die, and tandem die... Above 32% of our cold-forming tool business is progressive die.

Progressive Die is the ideal manufacturing method during the metal forming and it's often applied in high-volume production for its quick run speed and short set time. Besides, less metal scrap waste is another big advantage.

Metals usually used in progressive die:

1. Brass

2. Steel

3. Stainless Steel

4. Aluminum

5. Copper

| AUTOMOTIVE STAMPING DIE — PROGRESSIVE DIE

Progressive Die is the ideal manufacturing method during the metal forming and it's often applied in high-volume production for its quick run speed and short set time. Besides, less metal scrap waste is another big advantage.

Metals usually used in progressive die:

Brass

Steel

Stainless Steel

Aluminum

Copper

| VALUE-ADDED SERVICES

Synchronized Engineering

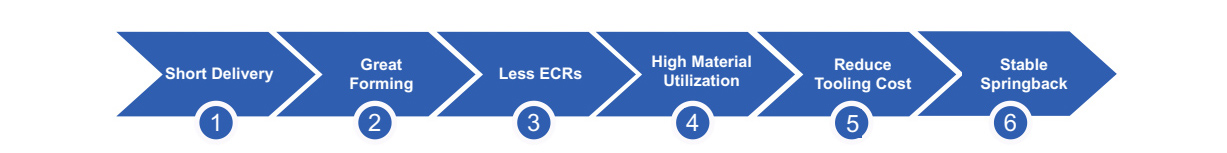

Believing in a win-win situation, Vision Tooling Group has built a special team to provide customers Synchronized Engineering support, commonly known as upfront die engineering even before customers win the program. With the proactive approach, customers significantly reduce the stamping die engineering hours, shorten stamping die development cycles, achieve better formability and less ECRs of automotive dies, increase material utilization, and ultimately lower the tooling investment.

Production Cost Optimization

When closely working with customers from process planning till tool designing, we always spend a lot of resources and efforts on maximizing the rates of material utilization & press stroke and minimizing the tool station numbers while ensuring production stability and repeatability.

Project Management

A group of advanced managing and technical staff endue us sufficient support to drive 3R(AR/SR/FR)triangle strategy from account management to engineering solution to fulfill the delivery responsibility, which means the fast and reliable tooling service. Meanwhile, our internal ERP system ensure we can track and monitor the detailed information about project execution vs plan in a timely manner, which includes, but not limited to, workload, cost, progress, defects, commitment, and risks. After evaluating each project status, our project managers provide the instant reports to both internal management team and external customers for just communication, alerts, or prompt correction, maintaining transparent for both parties.

Homeline Tryout & Local Support

As a tooling group, we believe in “Global Business & Local Services”. Vision Tooling Group is proud of its international professionals in the USA, Canada, Spain, Poland, South Africa who offer the local support on homeline commission, engineering review, new program launch, and convenient communication.

One-Stop Shop

As a top leader in the Chinese tooling industry with solid capability and substantial capacity, Vision Tooling Group offers an integral solution to customers by designing & building cold & hot-forming tools, checking fixtures and welding jigs in the global automotive industry.

| CAPACITY

Engineering Capacity

Engineering – All process and design engineers have Engineering Degree and worked on floor for years before moving to office.

Assembly - 100 die-makers for progressive dies and 124 die-makers for transfer dies work for two shifts with an average of 10-15 years tooling experience.

Manufacturing Capacity

129 sets of CNCs and 17 sets of presses, bring us high manufacturing capacity and achieve almost 16170 hours for machining and 4620 hours for manufacturing per week.

Quality Control

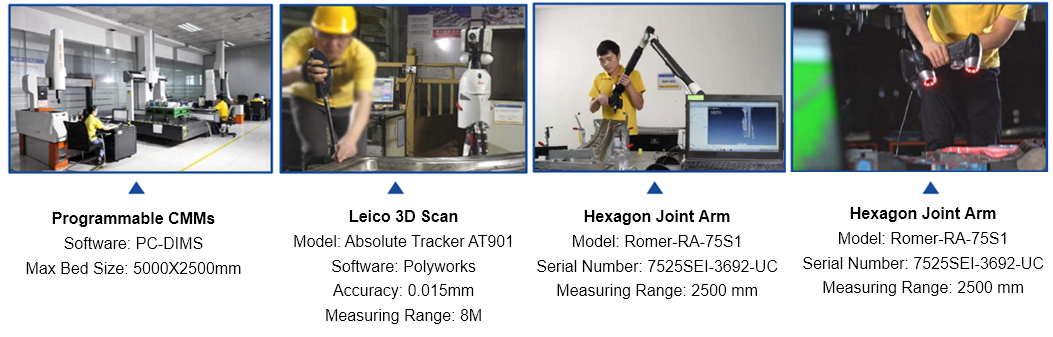

As for a leading enterprise of this industry,Vision Tooling gained rich experience in automotive die designing,manufacturing and delivering for more than 20 years,with current 1300 employees.We have not only capability, capacity,short delivery time and competitive price,but also one-stop shopping, pre-sales and after-sales value-added services.

Vision Tooling takes 'Provide No Defect Products' and 'Delivery on time' as its sacred mission,and continues to explore the most efficient services and technologies to serve the customers globally in world-class standard. please feel free to contact us. Additionally, you can request a quote today for customized tooling solutions.