hot forming

-

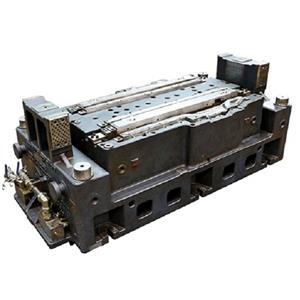

B Pillar Reinforcement Hot Forming Die

Automobile part Die; Hot forming Die; Hot Forming Die of Martensite Products; We Vision could design and manufacture B Pillar Reinforcement Hot Forming Die; We would like to deeply collaborate with customer and lead-in customer's standard.

Email Details -

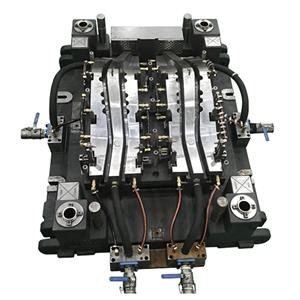

B Pillar Soft Zone Hot Forming Die

In the process of hot forming, quench different part with different velocity, even set a heating area to prevent martensite transformation to promote the performance in Energy Absorbing of the Soft Zone. The B pillar is the nearest component to the driver in cab, so it not only needs high strengh, but also need high impact energy absorptivity. Soft Zone Hot forming die tech could match this target perfectly. We possess this capability, and we are able to meet customer's request.

Email Details -

Patchwork Blank(PB)

Hot Forming Blank; Tailor Blank; Increase part strength also keep lighter weight;

Email Details -

Tailor Weld Blank(TWB)

Hot Forming Blank; Tailor Blank; Various shapes by welding different grade/thickness plates;

Email Details -

Laser Fixture

Auxillary Products of Hot Forming; Laser Fixture; The martensite product is too intensive to divide them with normal method, so the laser cutting is a necessary way, and most of time the simple laser fixture is just a auxiliary service for free.

Email Details -

Checking Fixture

Auxillary Products of Hot Forming; Checking Fixture; We vision group has a specialized subsidiary in producing checking fixture named Mission Gauge, but we hot forming division also could do that without any doubt.

Email Details -

Hot

Blanking Die

We vision has one stop service to Hot forming tool, coupling with formal die, the blanking die is a prerequisite most of the time. We could design and produce a blanking die within 75 days and we can process 5 sets of tools at the same time.

Email Details -

Prototype Hot Forming Die

At the situation of time limited or less demand quantity of product, Prototype tool could be a suitable solution. We vision could design and manufacture a hot forming prototype die within about 90 days. The product has nothing different with those from formal die.

Prototype Hot forming die No water channel hot forming die Short manufacturing cycle hot forming die hot metal stampingEmail Details -

China Side Impact Door Beam Hot Forming Die

2 Parts out of Door Beam Hot Forming Die; Martensite door beam could withstand up to 1800MPa press, reach a security level. Hot forming die takes on a better performance than cold forming.

Email Details