automobile part die

-

Hot

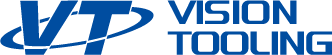

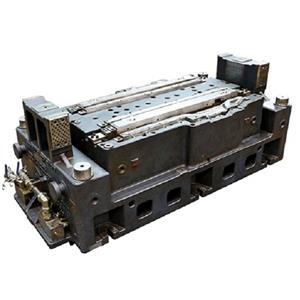

Door Beam Hot Forming Die

With demand of high strengh and hardness on this component, the hot forming process is applicated in producing this part. Martensite door beam could withstand up to 1800MPa press, reach a security level. Hot forming die, the useful tool in solving this issue, take on a better performance than cold forming. We vision has abound experience in design, manufacture and assembly in hot forming die, and you are always welcome to contact us.

Email Details -

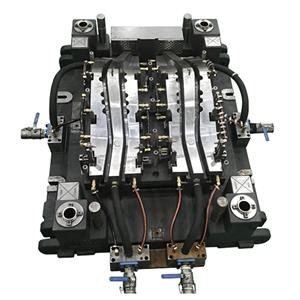

Central Floor Tunnel Hot Forming Die

Martensite Products; Central Floor Tunnel Hot Forming Die; Automobile component hot forming die; We Vision has abound experience in design, manufacture and assembly in hot forming die, and you are always welcome to contact us.

Email Details -

Hot

Middle Channel Hot Forming Die

Middle Channel Hot Forming Die; Most of time, the middle channel in a car doesn't have the fuction to withstand impact, but applicating hot forming component also could be a choice. We Vision has abound experience in design, manufacture and assembly in hot forming die, and you are always welcome to contact us.

Email Details -

Energy Absorption Side Member Hot Forming Die

The side member need to combine the foundmental elements and withstand the weight of car. In addition, it needs to dampe the continuous vibration while the car is runing. Hence, it's necessary to applicate hot forming tech on this part. The soft zone tech could be applicated on producing this part, so as to obsorb the impact energy efficiently. We vision has abound experience in design, manufacture and assembly in hot forming die, and you are always welcome to contact us.

Email Details -

Side Member Hot Forming Die

Martensite Products; Side Member Hot Forming Die; We Vision could design and manufacture Side Member Hot Forming Die; Martensite Products;

Email Details -

Lightening Car Weight Of Door Ring Hot Forming Die

Hot Forming Die for Lightening Car Weight; As Door ring is formed integrally, the overlap for welding is no longer needed. The weight could reduce by 20% accordingly. We Vision could design and manufacture Door Ring Hot Forming Die; Martensite Products; Cost saving hot forming tools; Integrative Forming Die; High material ultilization Hot Forming Die Tool.

Email Details -

Hot

Integrative Forming In Door Ring Hot Forming Die

Integrative Hot Forming Die; The quantity of Hot Forming Die could reduce from 4 sets to 2 sets (RH and LH). It's obvious that the cost of die could reduce a lot accordingly. We Vision could design and manufacture Door Ring Hot Forming Die; Martensite Products; Cost saving hot forming tools; Integrative Forming Die; High material ultilization Hot Forming Die Tool.

Email Details -

Hot

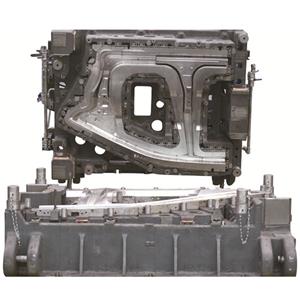

Door Ring Hot Forming Die

The A Pillar lower, B Pillar, Sill beam and A pillar top side member are designed integrative forming, so it could help to improve the material ultilization and reduce the weight of car. As we all know, the door ring integrative forming is always a difficulty, but that's not the pretext to us. We have overcame it over and over again. We vision has abound experience in design, manufacture and assembly in hot forming die, and you are always welcome to contact us.

Email Details -

B Pillar Hot Trimming In Die

Hot Trimming in Die; Compare to cold forming, there is no need for corresponding trimming Die; It could reduce by about 40% Laser Cost. Hot Forming Die of Martensite Products; Cost saving hot forming tools; We Vision could design and manufacture B Pillar Hot Triming in Die; Martensite Products; Cost saving hot forming tools.

Email Details