What Values can Vision Tooling Offer?

It is always a key question for the vast majority of the automotive OEMs or Tier-1s that HOW TO ACHIEVE THE MANUFACTURING BUSINESS? I can tell you the answer: to choose a reliable turnkey solution provider of automotive tooling to be your partner.

Vision Tooling who offers the products and services in one-stop can be your best choice. We provide not only automotive tools and dies, but also one-stop services for the entire manufacturing process. From pre-sales to after-sales,from die design to delivery, we can provide you a cost-effective solution that saves time, effort and money with competitive price, high quality and proved experience of big package project management &delivery for nearly 20 years.

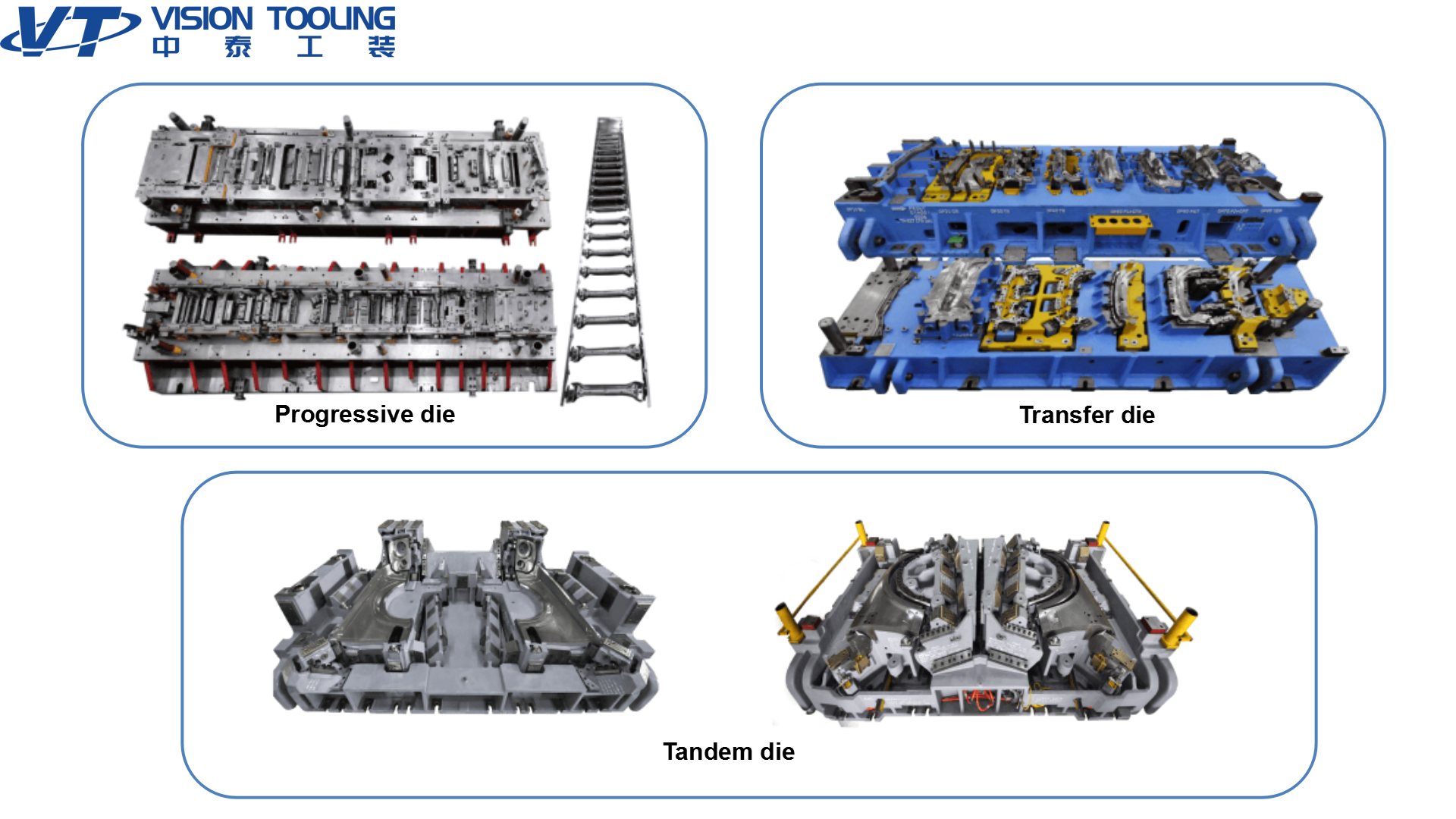

Business Modules

We divided our product modules into 3 parts:Progressive tool,transfer tool,tandem tool.And for our services,a turnkey solution will be tailored for customers including die design, stamping, assembling, testing, debugging, delivery....which works for the manufacturing of metal automotive components such as BIW,roof,seat,chassis,battery pack and so on.

High quality——Help your business grow up

-Quality assurance system

We establish a complete system to assure quality:

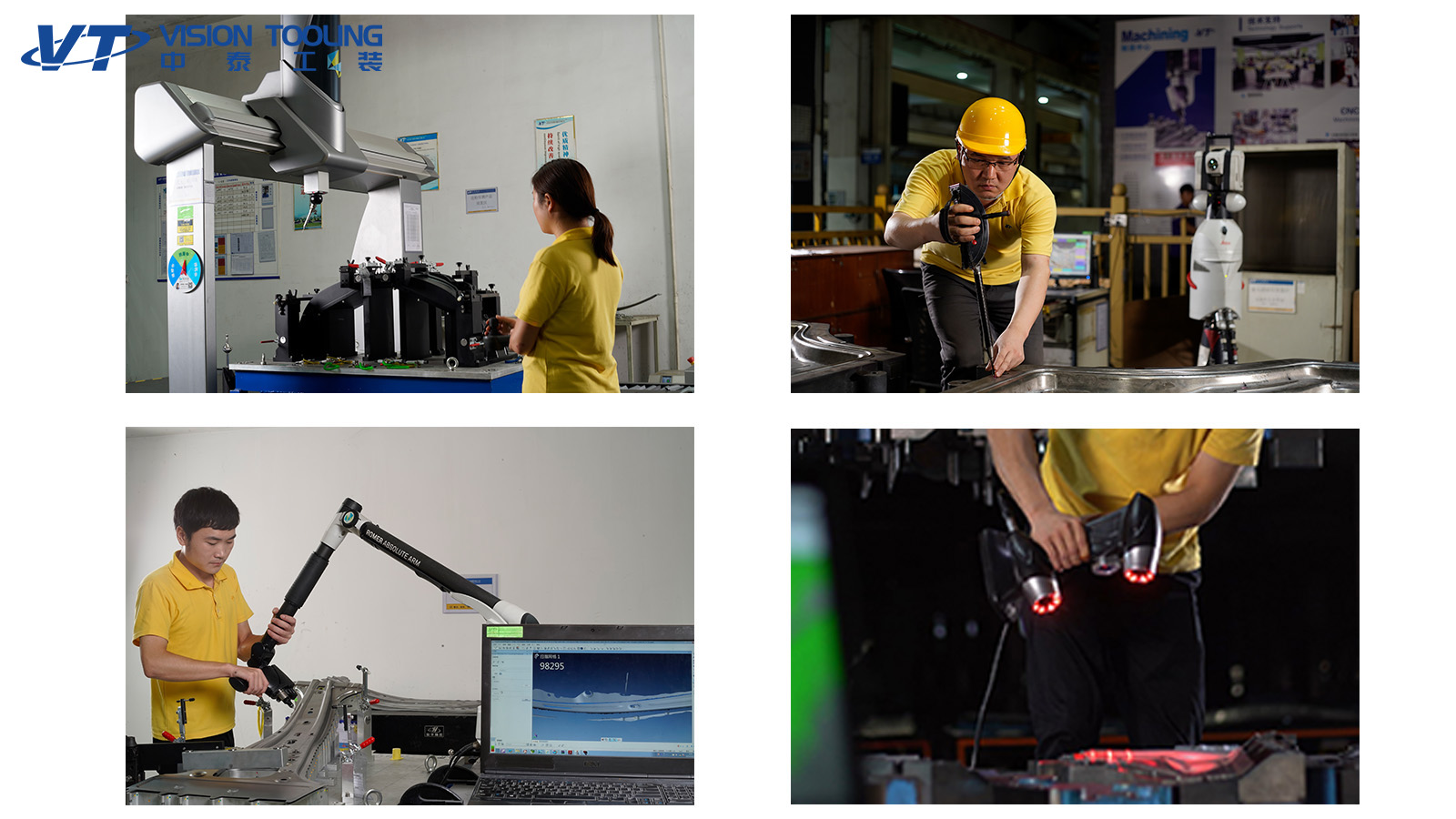

-High-end equipment

l Manufacturing devices:Presses up to 2000T

l Machining devices include: CNC with maximum bed size of 6.5m and precision ranging from 0.01 to 0.02mm,PARPAS 5 axis machine,large laser machine,automatic robots and processing machines...

l Inspection devices include:CMM up to 5000X2500mm,3D Scanning,Hand-held laser scanner and Hex - con joint arm.

Low price——Less budget than needed

Low cost leads to low price,Vision Tooling utilized optimization as much as possible to reduce the cost ---Simplify the parts, optimize the process, reduce the stations numbers and nitrogen pressure...

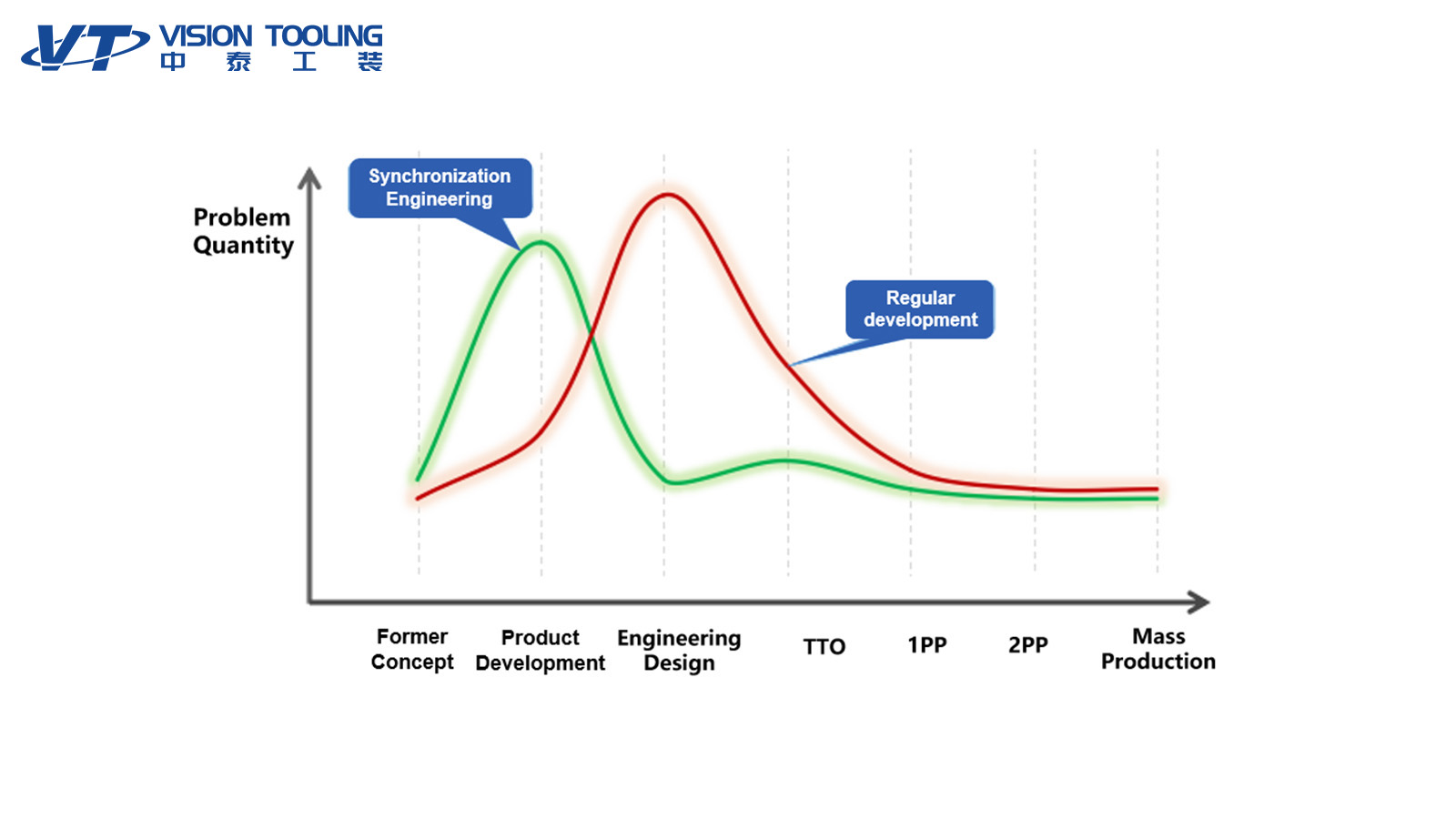

-Less changes

Find out the problem in advance to reduce the risk of changing and rectification cost in the future;

-Less materials

Optimize the contour and layout, improve the utilization rate of materials to reduce the stamping materials cost ;

Short delivery time——Speed up your production cycle

-Scale and Capacity

Vision Tooling’s 11 facilities have more than 65,000 square meters across Dongguan and Jiangxi with almost 150 sets of equipment and 1200 employees,which helps you speed up production cycle with a better design and faster output, therefore you can hit the market quicker.

-SE service

Product and process designed with parallel development shortens the lead time.

Reliable partnership ——You can rely on us for

-Certification

Vision Tooling has obtained IATF16949, ISO9001, ISO14001 standard.

-Reputation

We have earned a reputation for manufacturing the highest quality tooling of metals and composite materials.There are some international certifications from our clients:

-Professionalization

We have a professional engineering and assembly team consisting of 500 employees,which established a complete and reliable system to ensure that the every part of the die is reasonably stressed.

Please feel free to contact us at+86-13609687219 or visiontoolgroup@gmail.com