Tooling for a Technical and Lightweight Future

One hundred years of rapid automotive development benefited us a lot, it brought a convenient but polluted life at the same time. Waste and pollution are always the most concerned problems for Vision Tooling who engaged on automotive supply chain. As you can see, human suffered from Covid-19 for only 2 years,but animals and other lives seem like resting for many years and recovering a lot from humans’ activities. We should rethink ourselves and update the strategy of development.Vision Tooling are innovating the new techs and lightweight materials for not only traditional car but also EV & HEV all the time, we believe that future is towards to a more eco-friendly and less polluting world.

Technical Advantages

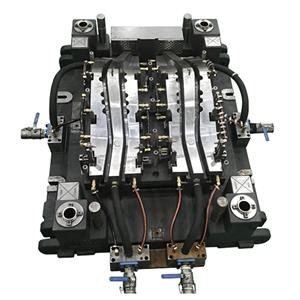

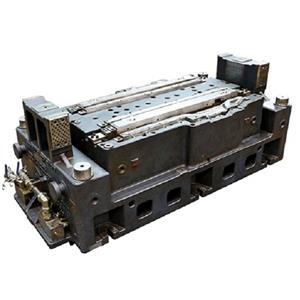

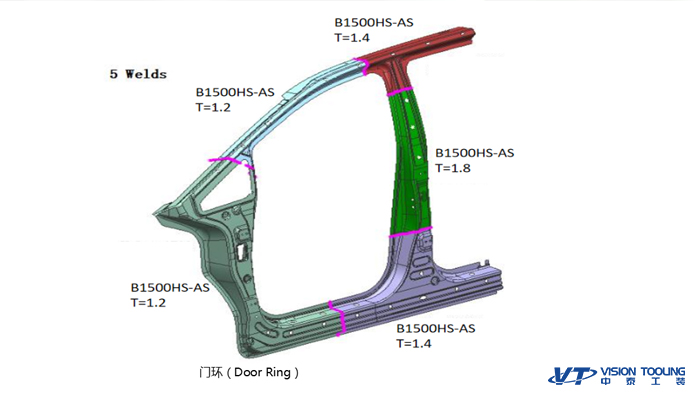

Innovative Hot Forming Tech

The whole-shaped hot forming technology in door ring was applied by Vision Tooling early in 2018, which can reduce the cost and waste and whose product has the characteristic of high intensity and durability.

Complete Parameter Database

Vision Tooling acquired various kinds of materials parameters with 20 years tooling experience.We established a complete parameter database and constantly update it, which helps we do SE analysis of product and process design parallel development,finally we can achieve less lead time and waste .

Lightweight Materials R&D

Lightweight materials lead to more possibilities, we have R&D on advanced new materials to ease the burden of not only customers’ anxiety but also resource shortage. Besides,there are more choices and possibilities for customers.

High-strength Steel

Aluminium

Magnesium

No matter what will happen in the future, we should find the right direction to be responsible for the environment. Vision Tooling is not only a toolshop serving for automotive metal stamping, but also an enterprise determined to contribute to society and mankind.

If you are interested in us, click www.vision-tool.com.cn to know more. Otherwise you can contact us at+86-13609687219 or visiontoolgroup@gmail.com