Tailored for your demand,Shaped for your business

As for a leading role in Chinese automotive stamping tooling field,Vision Tooling have been committed to R & D innovation and improving customer experience all the time.We serve for the auto motive OEMs and Tier’1s and take customers’ demands at first.

Your worries are our concerns.None of automotive manufactures can afford to waste time or quality issues during product launches,especially when it comes to a tooling problem which may make all your efforts in vain.So that Vision Tooling built a complete reliable system of project management to ensure the quality and time of your dies.

How We Prepare and Design

1、Customer Demand Leading-In:

Hold a project kick-off meeting to fully introduce customer demands and standards;

2、Customer Demand Training:

Train the operators about customer standards and do assessment tests;

3、Design Internal Review:

After the design is completed, internal review will be conducted against customer standards;

4、Design Customer Review:

We could review through video conferences and go to the customer side to provide face-to-face review services in order to quickly confirm the process and structural design;

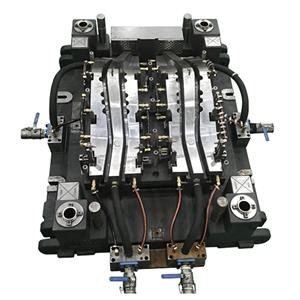

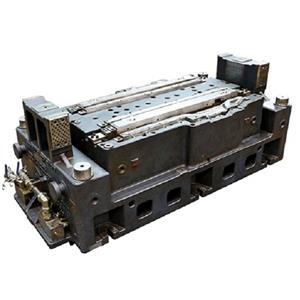

How We Process and Manufacture

7、Incoming Inspection:

We have specialized laboratories to do the customer-supplied try out material test to verify the design consistency, independent third-party institutions to do the steel materials test and professional TOMS detectors scan to do the casting inspection;

8、Processing Leica Scan Inspection:

Use laser scanning to detect whether the processed parts are within the tolerance range;

How we assemble and buy-off

9、Die Assembly Inspection:

Try to do pre-assembly to fit all parts first, and then complete full die assembly to ensure the correct clearance and mold integrity, and solve the problems which may cause during the try out process in advance;

10、Blue Spotting :

Carry out the grinding operation according to the blue spotting to ensure that each station fits well;

11、Internal Dies Tryout:

Our quality engineer would do the internal buy-off according to the customers' buy-off standard first and solve the problems in advance ;

12、Customer Buy-off:

We can provide customers with online or offline die buy-off;

Homeline Support

We could arrange our engineers to provide the homeline support all over the world to meet the customers' production requirement.

With the innovative and professional advantages, Vision Tooling has decades of experience and the proper equipment to meet your automotive metal stamping needs.Our in-house facilities allows us to manage the whole process easily and our capability of design and tryout enables us to identify deformations quickly so that we can repair it and reduce supply chain risk.Therefore, we can satisfied whatever you ask for.Our tools are tailored for your demand,shaped for your business.

If you are interested in our products,please contact us at+8601360987219 or visiontoolgroup@gmail.com